Summary

- How heat transfer printing works and when it’s the right choice

- The main pros, cons, and durability factors to consider

- Heat transfer vs screen printing vs DTG—clearly compared

- Best uses for custom apparel, small orders, and startups

If you’ve ever thought about custom T-shirts, hoodies, or branded apparel and wondered, “Is heat transfer printing actually worth it?”—you’re not alone.

Heat transfer printing has become one of the most popular methods for custom apparel, especially for small businesses, startups, and one-off designs.

Why?

Because it offers vibrant designs, low setup costs, and the flexibility to print exactly what you need—when you need it.

But here’s the honest truth: heat transfer printing isn’t perfect for every situation.

So, by the end of this guide, you’ll know whether heat transfer printing for custom apparel fits your design, budget, and order size.

What Is Heat Transfer Printing?

Heat transfer printing is a method where a design is printed onto a special transfer paper or film and then applied to fabric using heat and pressure.

Instead of printing ink directly onto the garment, the design is transferred onto it—kind of like a professional-grade iron-on, but far more advanced.

This process is widely used for:

- Custom T-shirts

- Personalized hoodies

- Event apparel

- Promotional products

It’s especially popular for small orders and custom designs where flexibility matters more than mass production.

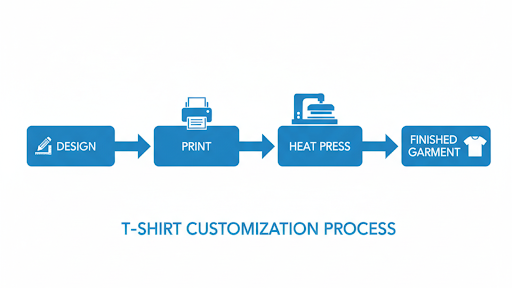

Heat Transfer Printing Process (Step-by-Step)

Let’s break the heat transfer printing process step by step—no technical jargon.

Design Creation: Your artwork is created digitally using design software.

Printing on Transfer Paper or Film: The design is printed onto:

- Transfer paper (for HTV or paper transfers), or

- Film (for DTF transfers)

Heat Press Application: The transfer is placed on the fabric and pressed using a heat press at a specific temperature, pressure, and time.

Cooling and Finishing: Depending on the method, the transfer is peeled hot or cold, and the garment is ready to wear.

This heat transfer vinyl printing process is simple, repeatable, and ideal for controlled, custom production.

Types of Heat Transfer Printing

Not all heat transfer printing is the same. The method you choose directly impacts print quality, feel, and durability.

Heat Transfer Vinyl (HTV)

HTV is best for:

- Simple logos

- Text-based designs

- Single or limited colors

Why people love it:

- Clean, bold results

- Great for names, numbers, and branding

Limitations:

- Not ideal for complex or photo-heavy designs

DTF (Direct-to-Film) Transfers

DTF has changed the game.

Best for:

- Full-color designs

- Detailed artwork

- Gradients and photos

DTF transfers offer excellent heat transfer printing quality, especially on cotton and blended fabrics.

Sublimation

Sublimation is often mentioned alongside heat transfer printing, but it has a major limitation:

- It only works on polyester or polyester-coated surfaces

That’s why it’s not always a go-to option for everyday apparel.

Advantages of Heat Transfer Printing

Let’s talk about why so many brands and creators choose heat transfer printing.

Cost-Effective for Small Orders

This is one of the biggest wins.

- No screens to create

- No heavy setup costs

- No minimum order requirements

That makes heat transfer printing for small orders perfect for startups, individuals, and testing new designs.

High-Quality, Vibrant & Detailed Designs

Want photo-quality prints?

Heat transfer printing delivers:

- Unlimited colors

- Sharp details

- Smooth gradients

This makes it ideal for branding where visuals matter.

Versatility Across Products

Heat transfer printing works on more than just T-shirts:

- Hoodies & sweatshirts

- Tote bags

- Hats

- Mugs & accessories

If you’re offering multiple product types, this flexibility is a huge advantage.

Easy to Start & Scale Slowly

Compared to screen printing, heat transfer printing:

- Requires less equipment

- Has minimal cleanup

- Is beginner-friendly

You can start small and scale only when demand grows.

On-Demand & Flexible Production

Transfers can be created and stored ahead of time.

This means:

- Faster turnaround

- Perfect for one-off or personalized orders

- Great for print-on-demand businesses

This is where we, The Apparel Pro, help businesses produce professional-quality custom apparel without unnecessary overhead.

Disadvantages of Heat Transfer Printing

Now for the honest part—because every printing method has trade-offs.

Durability Concerns

Over time, some transfers may:

- Crack

- Peel

- Fade

Compared to screen printing, heat transfer printing has a durability that is usually moderate, not permanent.

Not Ideal for Bulk Production

For large quantities:

- Production is slower per unit

- Cost per piece increases

That’s why heat transfer printing isn’t the best choice for mass orders.

Hand Feel & Comfort

Some transfers feel:

- Thicker fabric

- Less breathable

This depends heavily on transfer quality and application technique.

Heat Sensitivity & Material Limits

Not all fabrics tolerate high heat.

Certain materials may:

- Scorch

- Warp

- Lose texture

How to Reduce These Drawbacks

Good news—you can minimize most issues:

- Use high-quality transfers

- Follow the correct heat press settings

- Wash garments inside out with cold water

Choosing the right partner (like The Apparel Pro) makes a noticeable difference in final results.

Heat Transfer vs Screen Printing vs DTG

| Method | Best For | Cost | Durability | Order Size |

|---|---|---|---|---|

| Heat Transfer | Small, custom orders | Low | Moderate | No minimum |

| Screen Printing | Bulk orders | Medium | High | 30+ |

| DTG | Detailed small runs | Medium | High | No minimum |

Which Printing Method Should You Choose?

Ask yourself:

- How many pieces do I need?

- What fabric am I using?

- Is my design simple or detailed?

- What’s my budget?

If flexibility and customization matter most, heat transfer vs screen printing often comes down to order size and design complexity.

Best Uses of Heat Transfer Printing

Personalized & Custom Apparel

Perfect for:

- Events

- Gifts

- Brand merchandise

Photo & Complex Graphics

Heat transfer printing handles:

- Multi-color logos

- Images

- Gradients

Startups & Small Businesses

Low risk. Low investment. High impact.

Mixed & On-Demand Orders

Different designs on different products?

No problem.

These are some of the best uses of heat transfer printing for modern businesses.

Who Should Choose Heat Transfer Printing?

Heat transfer printing is ideal for:

- Small apparel brands

- Event organizers

- Etsy sellers

- Corporate gifting

- Local businesses serving both local & nationwide customers

Final Thoughts: Is Heat Transfer Printing Worth It?

Yes—when used the right way.

It’s perfect for:

- Small orders

- Custom designs

- Startups testing new ideas

But if you’re producing thousands of identical shirts, other methods may serve you better.

If you’re looking for high-quality, flexible custom apparel without minimums, working with a trusted provider makes all the difference.

So, Ready to bring your designs to life?

Explore custom heat transfer printing solutions with The Apparel Pro and create apparel that actually fits your vision—without overpaying or overproducing.

Let’s turn your ideas into a wearable reality.

Frequently Asked Questions

What are the cons of heat transfer printing?

One of the main drawbacks of heat transfer printing is durability. Over time, prints may crack, peel, or fade—especially if low-quality materials or incorrect heat settings are used. Some transfers can also feel heavier on the fabric, which may affect breathability and comfort.

What are the disadvantages of heat transfer?

Heat transfer printing isn’t the best option for large bulk orders because production is slower and costs increase as volume grows. It also has material limitations, as certain fabrics cannot handle the high heat required during the transfer process.

What lasts longer, HTV or DTF?

DTF transfers typically last longer for detailed, full-color designs because the ink bonds more evenly with the fabric. HTV works well for simple logos and text, but may show wear sooner on stretchy garments or with frequent washing.

What can heat transfer paper be used for?

Heat transfer paper is commonly used on T-shirts, hoodies, tote bags, hats, and similar fabric-based products. The final result depends on using the right paper type and fabric combination for the intended application.

Rush Delivery: As soon as February 11

Rush Delivery: As soon as February 11